Coastlines:

- NOAA-NGDC Coastline extractor web site

-

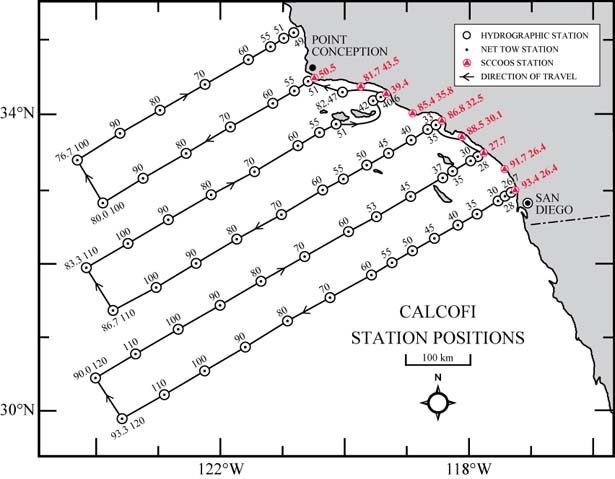

CalCOFI coastlines

- 75 stations: 29 to 36degN, -125 to -115deg W Matlab dat file

- 113 stations: 28.5 to 38.5degN, -125 to -115W Matlab dat file

|

|

| 29 to 36degN, -125 to -115deg W | 28.5 to 38.5degN, -125 to -115W |

- Surfer mapping program 75 station template files; horizontal contour.srf, coastline.bln, lines 93-77 blank file to apply to gridded data

When finally adopted for all station work on CalCOFI 9308NM, the CTD and sensors were mounted on a 24-bottle rosette frame. The separate hydrographic and primary productivity casts were combined into one 24-bottle CTD-rosette cast.

Other noteworthy events: the Seabird 911 system was upgraded to 911plus in 1998. At the same time, the General Oceanics 24-place pylons were replaced with a Seabird SBE32 carousels.

Originally deployed with one set of temperature & conductivity sensors, a second pair, with their own pump, was added July 1998.

LTER joined CalCOFI cruises in Nov 2004, adding an ISUS nitrate sensor to the CTD and additional seawater analyses.

| CalCOFI CTD HISTORY | ||||

| YYYYMM | CruiseSC | Date | Author | Description |

| 201008 | 1008NH | JRW | 3500m deep CTD casts performed on stas 90.90 & 80.90 | |

| 201004 | 1004MF | JRW | 12 Niskin bottles only; 2 CTD casts performed on prodo stations to target prodo depths; not enough wire for deep casts | |

| 201001 | 1001NH | 17-Jan-2010, 29-Jan-2013 | JRW | 3500m deep CTD casts changed to stas 90.90 & 80.90 |

| 200911 | 0911NH | 6-Nov-2009 | J.Wilkinson | New SBE9plus CTD (09P53161-0936; 6800m) deployed; new sensor pairs T,C,& Ox + Seabird pH sensor, transmissometer, altimeter. New Seapoint fluorometer NOT deployed. |

| 200911 | 0911NH | 10-Nov-2009, 20-Nov-2009 | JRW | 3500m deep CTD casts performed on stas 90.100 & 80.100; Note for 3500m casts the following sensors are removed: ISUS & battery, PAR & pH. |

| 200907 | 0907MH | 14-Jul-2009 | J.Wilkinson | New version 2 Deck Unit purchased (27-Mar-2009); offsets secondary conductivity automatically; plus complete new set of sensors: SBE14 Remote depth readout; SBE18 pH sensor; QSP-2300 PAR; Wetlabs C-Star transmissometer; Teledyne Altimeter (on older 'fish') |

| 200411 | 0411RR | 2-Nov-2004 | J.Wilkinson | Satlantic ISUS nitrate sensor with battery pack added to CTD-rosette sensor array. |

| 199808 | 31-Aug-1998 | J.Wilkinson | CTD SN 93235-0203 (Arnold) upgraded to 9plus; 2058 rated | |

| 199807 | 9807NH | 08-Jul-1998 | J.Wilkinson | Added a second pair of temperature & conductivity; prompted by failure on previous cruise of the primary conductivity sensor - returned from calibration cracked. |

| 199807 | 01-Jul-1998 | J.Wilkinson | SBE32 Carousel Water Sampler replaces General Oceanics Pylon (Model 1015 purchased 8/1989) | |

| 199805 | 26-May-1998 | J.Wilkinson | CTD Sn 91338-1 (Homer) upgrade to 9plus; 3400m rating | |

| 199308 | 9308NH | 11-Aug-1993 | J.Wilkinson | Seabird CTD officially used for all 66 stations; 66 casts; 20 bottles |

| 199210 | 9210NH | 26-Sep1992 | J.Wilkinson | Seabird CTD used for prodo casts; 13 casts; 12 bottles; Ed Renger Prodo Cast operator |

| 199207 | 9207NH | 02-Jul-1992 | J.Wilkinson | Seabird CTD tested during prodo casts; 14 casts; 10 bottles |

| 199204 | 9204JD | 26-Apr-1992 | J.Wilkinson | One cast; conductive wire winch failure; hanging prodo cast on hydrowire |

| 199202 | 9202JD | 29-Jan-1992 | J.Wilkinson | Seabird CTD tested during prodo casts; 14 casts; 10 bottles |

| 199110 | 9110NH | 28-Sep-1991 | J.Wilkinson | New and improved Seabird CTD tested; 13 casts; 12 bottles. |

| 199011 | 9011NH | 8-Nov-1990 | J.Wilkinson | Second test of Seabird CTD on CalCOFI; 12 casts; 9 bottles. |

| 199003 | 9003JD | 4 Mar 1990 | J.Wilkinson | Seabird CTD first tested on CalCOFI; 13 casts; 10 bottles |

The California Cooperative Oceanic Fisheries Investigations (CalCOFI) are a unique partnership of the California Department of Fish and Wildlife, the NOAA Fisheries Service and the Scripps Institution of Oceanography. The organization was formed in 1949 to study the ecological aspects of the collapse of the sardine populations off California. Today its focus has shifted to the study of the marine environment off the coast of California and the management of its living resources. The organization hosts an annual conference, publishes data reports and a scientific journal and maintains a publicly accessible data server (www.calcofi.com).

The Field Program

Since 1949, CalCOFI has organized cruises to measure the physical and chemical properties of the California Current System and census populations of organisms from phytoplankton to avifauna. This is the foremost observational oceanography program in the United States.

Currently, 18 to 28 day cruises are conducted quarterly - summer & fall cruises are typically 18 days, winter & spring cruises are longer. Scripps and NOAA provide equally in terms of ship time, personnel, and other cruise-related costs. On each cruise a grid of 75 stations off Southern California is occupied. Winter & spring cruise may occupy stations just north of Pt Conception up to Monterey or San Francisco. At each station a suite of physical and chemical measurements are made to characterize the environment and map the distribution and abundance of phytoplankton, zooplankton, fish eggs and larvae.

Core measurements

- temperature, salinity, oxygen, nutrients

- water masses and currents

- primary production

- phyto- and zooplankton biomass & biodiversity

- meteorological observations

- distribution and abundance of fish eggs & larvae

- marine birds & mammal census; marine mammal acoustic recordings

-

fisheries acoustics

CalCOFI hydrographic CTD data, particularly the thermodynamic properties, are computed by Seasoft based on EOS-80. Temperatures, typically from the primary temperature sensor, are merged with bottle sample data into station files which produce the hydrographic database and other data products, Hydrographic Reports, figures, IEHs. CTD sensor salinities, and oxygen values may also replace bottle measurements on mistrip or missing samples.

Currently (May 2014) no TEOS-10 calculation for absolute salinities are calculated.

Information from Seasoft v7.23.1 (May 2014)

Algorithms used for calculation of derived parameters in Data Conversion, Derive, Sea Plot, SeaCalc III [EOS-80 (Practical Salinity) tab], and Seasave are identical, except as noted in Derived Parameter Formulas (EOS-80; Practical Salinity), and are based on EOS-80 equations.

Derived Parameter Formulas (EOS-80)

For formulas for the calculation of conductivity, temperature, and pressure, see the calibration sheets for your instrument.

Formulas for the computation of salinity, density, potential temperature, specific volume anomaly, and sound velocity were obtained from "Algorithms for computation of fundamental properties of seawater", by N.P. Fofonoff and R.C Millard Jr.; Unesco technical papers in marine science #44, 1983.

- Temperature used for calculating derived variables is IPTS-68, except as noted. Following the recommendation of JPOTS, T68 is assumed to be 1.00024 * T90 (-2 to 35 °C).

- Salinity is PSS-78 (Practical Salinity) (see Application Note 14: 1978 Practical Salinity Scale on our website). By definition, PSS-78 is valid only in the range of 2 to 42 psu. Sea-Bird uses the PSS-78 algorithm in our software, without regard to those limitations on the valid range. Unesco technical papers in marine science 62 "Salinity and density of seawater: Tables for high salinities (42 to 50)" provides a method for calculating salinity in the higher range (http://unesdoc.unesco.org/images/0009/000964/096451mb.pdf).

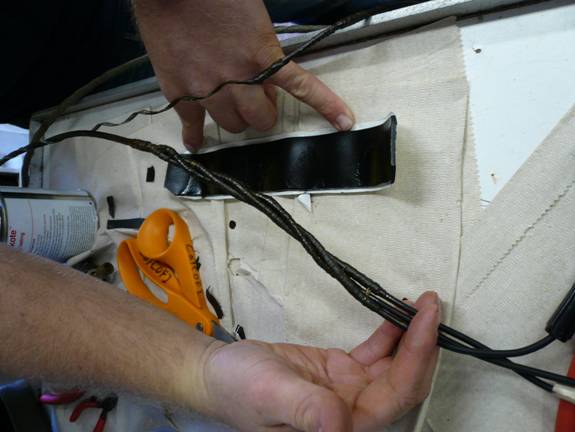

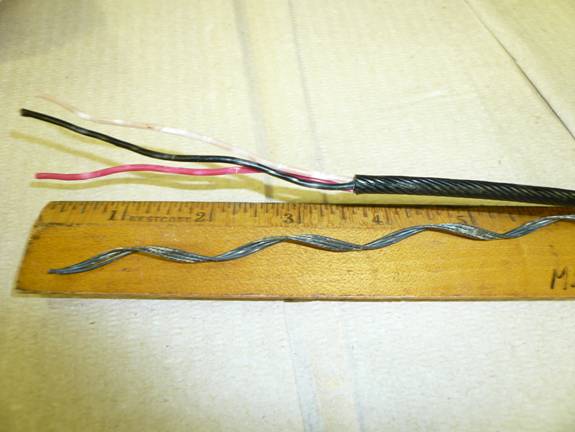

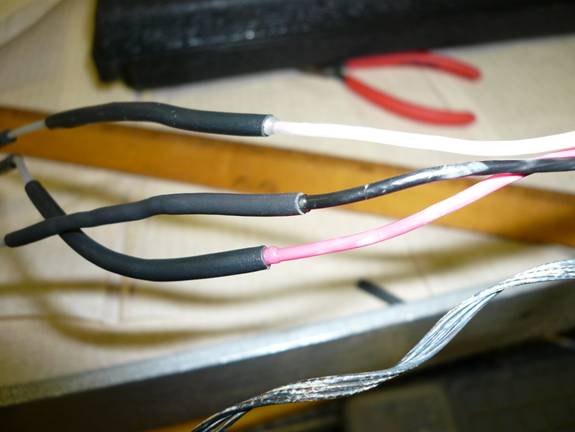

The SIO-CalCOFI method of termination is one of many techniques used to interface a CTD on a conductive wire. Over the years, our method has evolved - this document describes our current technique.

Since many ships have a 3-conductor wire (3 internal wires plus shield), each wire is terminated separately, isolating it from the other wires. If any single conductor fails over the course of the cruise, it can be disconnected from the CTD pigtail without having to re-terminate. Although each of the 3 wires & shield has its own connector, the CTD pigtail can combines the two 'best' conductive wires for the signal, reducing resistance. The remaining conductor is a spare or can be paired with the shield as ground. CalCOFI typically uses only the shield for ground.

On vessels with a single-wire conductive sea-cable, the standard termination (signal=conductive wire; ground=shield) method is used with a Seabird two-pin CTD pigtail. The wire stripping, soldering, and sealing of the termination is done the same way but with only one wire and shield. A standard two-pin Seabird termination pigtail is interfaced with the ship's single conductor wire. Wire shield is used for ground.

| Part 1: The termination | (click photos for larger image) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Part II: The Sea-cable Connection | |

|

|

| Part III: The Rigging | |

|

|

|

|

|

|

|

|

|

|

|

|

| Tips & Reminders | |

|

|

CalCOFI Data Management: Setting Community Standards

(presented as a poster at the 2007 CalCOFI Conference by James Wilkinson, Karen Baker & Richard Charter)

Introduction

CalCOFI represents a partnership of multiple agencies conducting quarterly joint oceanographic cruises. CalCOFI cruise participants work as a cohesive cross-agency unit to accomplish cruise objectives. Ancillary researchers frequently integrate their field measurements and sampling with the long-term core CalCOFI measurements and samples. Once a cruise concludes, however, this cohesive unit disperses; individuals return to their respective agencies and labs to process samples and analyze data. Each group uses legacy lab or agency specific methods and software to generate data products in local formats. These diverse data processing methods, products, and storage formats create challenges for merging final datasets. Development and incorporation of shared data management practices and joint community standards enable data integration.

CalCOFI represents a partnership of multiple agencies conducting quarterly joint oceanographic cruises. CalCOFI cruise participants work as a cohesive cross-agency unit to accomplish cruise objectives. Ancillary researchers frequently integrate their field measurements and sampling with the long-term core CalCOFI measurements and samples. Once a cruise concludes, however, this cohesive unit disperses; individuals return to their respective agencies and labs to process samples and analyze data. Each group uses legacy lab or agency specific methods and software to generate data products in local formats. These diverse data processing methods, products, and storage formats create challenges for merging final datasets. Development and incorporation of shared data management practices and joint community standards enable data integration.

Establishing Shared Practices

Identifying and establishing common, queriable columns, such as order occupied and event number, and including them in final data products allows heterogeneous datasets to be related. In addition, standardizing data elements such as column headers, date-time specifications, spatial designations such as GPS decimal format are easy to implement with minimal impact on existing data production. Standard, linkable data elements allow ingestion into relational databases, applications, and other analytical tools such as Data Zoo using import templates.

CalCOFI Standardization Strategies:

- Persistent vocabulary and formats with defined standard data column label

-

Date & position format conventions

- Date: YYYY/MM/DD HHMMSS.S UTC

- Position: 32.53455, -117.23433

- Standard Line Station grid designations example: line 93.3, station 120.0. Traditionally, integer values are used to describe a CalCOFI line.sta, 93.120 for example. But with the integration of SCCOOS stations as part of the regular 75 station pattern, the decimal notation improves line.station distinguishability.

- Order-occupied numbering for sequential stations

- Event numbers for distinguishing all station activities that generate data

- Data distribution in non-proprietary format such as comma-delimited ascii files (.csv) in addition to legacy IEH for data warehouses like NODC who expect & can ingest IEH.

- Metadata - definitions of measurements & equipment; translation tables for different unit attributes.

Shared Practices Begin in the Field

With quarterly cruises generating a persistent influx of data, the CalCOFI technical team must maintain an established routine to keep pace. Changes in procedure or protocol impact the expediency of the ongoing process. To minimize the impact of new data integration practices, the change process best begins at sea. Careful attention to sta activities & event logs create both a shared index and initiates a dialogue about organizational design.

Figure 1: Typical CalCOFI-SIO Data Flow from Field Collection to Publication

Figure 2: Typical CalCOFI-SWFSC Data Flow from Field Collection to Publication

Developing Data Integration Standards

At sea:

-

Water samples are collected, logged & analysed. Net tows collected, logged, & preserved.

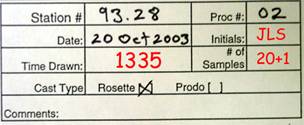

- Standard 1: all logs use joint standard formats with common station, event number & order occupied indexes.

-

Preliminary data processing and quality control of individual samples types: salinity, nutrients, oxygen, chlorophyll.

- Standard 2: event logs, sample logs, & analytical output files are available on the network, all include common sample indices.

-

Traditional data processing; merging of individual data types into a combined, local ascii format using in-house software. Preliminary data are merged, quality control protocols are applied. Final compilation and data publication: CalCOFI Data Reports as txt, pdf, and html; contour plots; IEH files (proprietary legacy format), all web accessible.

- Standard 3: Station & cast information, bottle, and CTD data are merged into a non-proprietary csv with common, queriable elements, standard formats, & labels.

-

Net tow data are processed with the flow meter calibrations and depth of tow, volume of water strained and other variables are calculated and added to the net tow dataset. The bongo tows are then volumed.

- Standard 4: A plankton volume report is generated with common elements, standard formats and labels.

-

The plankton samples are then sorted removing all fish eggs, larvae and squid paralarvae. The major species (sardine, anchovy, and hake) are identified and sized at the time of sorting. The remaining plankton sample goes to the SIO archives. The unidentified eggs and larvae are identified in the ichthyoplankton identification lab. The fish eggs and larvae are then archived in the NMFS ichthyoplankton archives.

- Standard 5: An eggs and larvae dataset is produced in a standard format. An annual ichthyoplankton data report is produced in a standard format once all the cruises of the year have been identified.

Cross-Project Data Interfacing

CalCOFI cruises generate multiple data formats such as station data; continuous meteorological, ADCP, & SCIMS (universal format SCS or MET continuous data + event numbers) data; avifauna & marine mammal visual observations and acoustic recordings. Each research group has their own data publishing goals. It must be the goal of all data-producing participants to generate a standard product with common indices for use by the data community. CalCOFI-SIO & CalCOFI-SWFSC are establishing a common vocabulary and standardizing final data formats & practices so hydrographic, zooplankton, and ichthyologic data can be integrated.

Data Interfacing Strategies:

- Establish a shared data product

- Consider your final data and what you are able to share with the data community – some data processes take longer.

- Develop a standard, persistent format so cross-project partners can plan for a consistent data format and design ingestion mechanisms such as import templates.

- Think collaboratively

- The Ocean Informatics team is working together to automate the importing of CalCOFI data into DataZoo, a cross-project, web-based, information system.

Acknowledgements

We would like to recognize the added work done by field participants - ship and scientific staff - in helping to plan forward for data integration and by the cross-project community of participants working to create a common information environment. This work is supported by NOAA CalCOFI SIO and SWFSC together with the NSF LTER California Current Ecosystem and the Ocean Informatics team.

This information was presented as a poster at CalCOFI Conference 2007 (image).

Authors: James Wilkinson, Karen Baker from Scripps Institution of Oceanography and Richard Charter from NOAA Southwest Fisheries Science Center

Sample Drawing:

1.  Chl samples are drawn on all rosette bottles tripped from ~200m to surface; sampling on a standard 20-bottle cast usually starts at #7 but refer to electronic sample log. For shallow stations, all the bottles may be sampled; noontime prodo casts may have extra bottles to sample; duplicate depths are usually skipped. Refer to the electronic sample log to verify which bottles to sample or ask the watchleader.

Chl samples are drawn on all rosette bottles tripped from ~200m to surface; sampling on a standard 20-bottle cast usually starts at #7 but refer to electronic sample log. For shallow stations, all the bottles may be sampled; noontime prodo casts may have extra bottles to sample; duplicate depths are usually skipped. Refer to the electronic sample log to verify which bottles to sample or ask the watchleader.

2. Drawing from the middle valve, add ~20mls, cap loosely, rinse-shake then dump; three rinses. Double-check the sample bottle number matches the rosette bottle number (often).

3. Chl samples are volumetric so after rinsing, fill it completely, cap loosely, tap the bottle gently against the rosette frame to dislodge any small bubbles then top-off, cap tightly, invert the bottle – if you see a large bubble, top-off and check again. Squeezing the sides of the bottle can change the sample volume so cup the bottle in your palm during the final fill to minimize this problem.

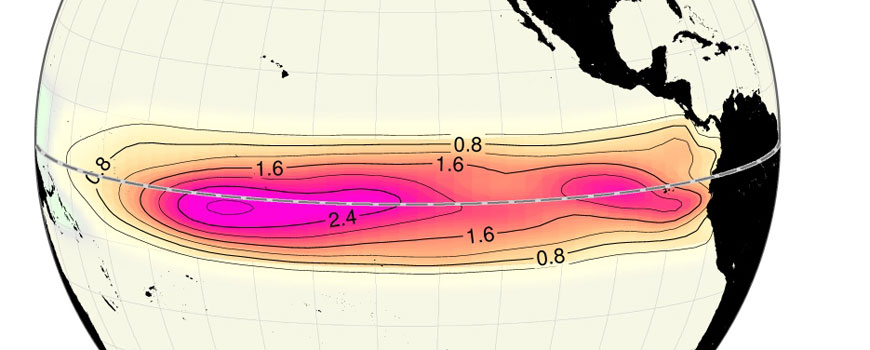

The graphic below is a reproduction from an article in which researchers at SIO are corroborating these predictions with observations.

El Niño is an abnormal warming phase in the Pacific Ocean Sea Surface Temperature (SST), while the abnormal cooling is known as La Niña - these shifts are part of the El Niño Southern Oscillation or ENSO. The current ENSO phase is often quantized by a deviation from normally observed SST using the Oceanic Niño Index or ONI. While El Niño and its counterpart cooling phase La Niña are still being researched, the seasonal effects are becoming well understood with long term data sets.

Using the table below from NOAA's Climate Prediction Center in conjunction with the CalCOFI database - can offer information on how the environment has reacted in response to the different phases and intensities of the ENSO.

- Retrieve an empty nutrient rack from the lab fridge if needed and record the color key with CESL electronic sample log.

- Wear latex or vinyl gloves; never touch the inside of the cap or tube since residue from your glove can contaminate the sample. If unavoidable or you drop the lid – rinse several times before capping the sample.

- Nutrients are normally drawn from the middle valve – fill the tube with ~25mls, cap loosely, shake/rinse then dump. Repeat three times.

- Double check the tube number matches the rosette bottle number.

- Fill the tube completely then flick out several mls so the sample reaches the base of the neck/threads. Cap tightly.

- Draw one sample per rosette bottle.

-

Once all the nutrient samples are drawn:

-

Carefully tip the nutrient rack until you can see the seawater sample through the cap of each tube – if a tube is empty, double-check the sample log and fill if necessary.

- fill out a sample label (from the sample label clipboard) with the time, your initials, total number of samples

-

Carefully tip the nutrient rack until you can see the seawater sample through the cap of each tube – if a tube is empty, double-check the sample log and fill if necessary.

-

Wrap the label around tube #1 and carefully re-insert into rack

- return the filled rack to the nutrient fridge right away.

- add your initials to the bottom of CESL's sample log’s nutrient column

Common mistakes are empty tubes that shouldn’t be; contaminated samples; and duplicate draws – two sample tubes filled from the same bottle

Seasoft computes PAR using the following equation:

PAR = [multiplier * (109 * 10(V-B) / M) / calibration constant] + offset

Enter the following coefficients in the CTD configuration file:

M = 1.0 (Notes 2 and 3)

B = 0.0 (Notes 2 and 3)

calibration constant = 105 / Cw (Notes 2 and 4)

multiplier = 1.0 for output units of μEinsteins/m2•sec (Note 5)

offset = - (104 * Cw * 10V) (Note 6)

Notes:

- In our Seasoft V2 suite of programs, edit the CTD configuration (.con or .xmlcon) file using the Configure Inputs menu in Seasave V7 (real-time data acquisition software) or the Configure menu in SBE Data Processing (data processing software).

- Sea-Bird provides two calibration sheets for the PAR sensor in the CTD manual:

- Calibration sheet generated by Biospherical, which contains Biospherical’s calibration data.

- Calibration sheet generated by Sea-Bird, which incorporates the Biospherical data and generates M, B, and calibration constant needed for entry in Sea-Bird software (saving the user from doing the math).

- For all SBE 911plus, 16, 16plus, 16plus-IM, 16plus V2, 16plus-IM V2, 19, 19plus, 19plus V2, 25, and 25plus CTDs, M = 1.0. For SBE 9/11 systems built before 1993 that have differential input amplifiers, M = 2; consult your SBE 9 manual or contact factory for further information. B should always be set to 0.0.

- Cw is the wet μEinsteins/cm2•sec coefficient from the Biospherical calibration sheet. A typical value is 4.00 x 10 -5.

-

The multiplier can be used to calculate irradiance in units other than μEinsteins/m2•sec. See Application Note 11General for multiplier values for other units.

The multiplier can also be used to scale the data, to compare the shape of data sets taken at disparate light levels. For example, a multiplier of 10 would make a 10 μEinsteins/m2•sec light level plot as 100 μEinsteins/m2•sec. -

Offset (μEinsteins/m2•sec) = - (104 * Cw * 10V), where V is the dark voltage.

For typical values (Cw = 4.00 x 10 -5 and Dark Voltage = 0.150), offset = -0.5650.

The dark voltage may be obtained from:

- Biospherical calibration certificate for your sensor, or

- CTD PAR voltage channel with the sensor covered (dark) — in Seasave V7, display the voltage output of the PAR sensor channel.

Instead of using the dark voltage to calculate the offset, you can also directly obtain the offset using the following method: Enter M, B, and Calibration constant, and set offset = 0.0 in the configuration (.con or .xmlcon) file. In Seasave V7, display the calculated PAR output with the sensor dark; then enter the negative of this reading as the offset in the configuration file.

Mathematical Derivation

-

Using the sensor output in volts (V), Biospherical calculates:

light (μEinsteins/cm2•sec) = Cw * (10Light Signal Voltage - 10Dark Voltage). -

Seasoft calculates μEinsteins/m2•sec = [multiplier * 109 * 10(V - B) / M) / Calibration constant] + offset

where M, B, Calibration constant, and offset are the Seasoft coefficients entered in the CTD configuration file. - To determine Calibration constant, let B = 0.0, M = 1.0, multiplier = 1.0. Equating the Biospherical and Seasoft relationships:

104 (cm2/m2) * Cw * (10Light Signal Voltage - 10Dark Voltage) = (109 * 10V) / Calibration constant + offset

Since offset = - (104 * Cw * 10Dark Voltage), and V = Light Signal Voltage:

Calibration constant = 109 / (104 * Cw) = 105 / Cw

Example: If Wet calibration factor = 4.00 * 10-5 μEinsteins/cm2•sec, then C = 2,500,000,000 (for entry into configuration file).

Notes:

- See Application Note 11S for integrating a Surface PAR sensor with the SBE 11plus Deck Unit (used with the SBE 9plus CTD).

- See Application Note 47 for integrating a Surface PAR sensor with the SBE 33 or 36 Deck Unit (used with the SBE 16, 16plus, 16plus V2, 19, 19plus, 19plus V2, 25, or 25plus CTD).

Subcategories

CalCOFI Handbook

The CalCOFI Handbook is a compilation of information for cruise participants. It explains many aspects of the science performed at sea, particularly the sample drawing methods for each sample type.

Data Formats

CalCOFI Data File Formats

Methods

CalCOFI standard practices for sample analysis, data processing, metadata & general methodology.

Software

SIO-CalCOFI software used at-sea and ashore, developed by the SIO CalCOFI Technical Group. Plus other software: auto-titrator oxygen analysis software developed by SIO's Ocean Data Facility; Seabird Seasoft & Data Processing software; Microsoft Office, Ultraedit, Ztree, hxD hex editor, Matlab, Surfer, Ocean Data View.